The recycling process for aluminum saves tremendous amounts of energy, reduces waste in landfills, and conserves natural resources that would otherwise be extracted through mining operations. Understanding what happens to recycled aluminum cans reveals not only an impressive feat of engineering and logistics but also highlights why consumer participation in recycling programs remains crucial for environmental sustainability and economic efficiency.

This blog will walk you through every step of the aluminum can recycling process, explore the significant environmental and economic benefits, and explain how proper recycling practices contribute to a circular economy that benefits businesses, communities, and the environment alike.

Key Takeaways

- Aluminum recycling is highly efficient, using only 5% of the energy required to produce new aluminum from mined bauxite, which dramatically reduces greenhouse gas emissions and air pollution.

- The aluminum recycling process is fast and circular, allowing used cans to become new products—often returning to store shelves within 60 days.

- Recycling aluminum preserves natural resources, eliminating the need to mine large amounts of bauxite ore and reducing the environmental damage associated with extraction and refining.

- Advancements in recycling technology, including AI-driven sorting and robotic systems, are improving material recovery accuracy, reducing contamination, and increasing processing efficiency.

- Consumer participation plays a vital role, as placing cans in recycling bins ensures they enter a sustainable cycle that conserves energy, reduces landfill waste, and supports a cleaner, more resilient environment.

Why Aluminum Cans Are Recycled

The environmental impact of aluminum production makes recycling these materials one of the most important waste management priorities. When aluminum is created from raw materials, the process begins with bauxite ore extraction, which requires extensive mining operations that disrupt ecosystems and consume vast amounts of energy. The transformation from bauxite to usable aluminum involves multiple energy-intensive steps, including chemical processing, refining, and electrolytic smelting, that consume enormous quantities of electricity.

The economic benefits of recycling aluminum extend beyond energy savings, with closed-loop recycling maintaining material value that depends on stable collection systems, which becomes even more evident when recognizing how to secure your trash bin against wind and animals to prevent loss of recyclable materials. Closed-loop recycling systems allow aluminum to maintain its structural integrity and performance characteristics through infinite recycling cycles, making recycled aluminum as valuable as newly produced metal. This creates a stable market for recycled material that supports jobs throughout the recycling industry, from collection and transport to processing and manufacturing.

The Recycling Process: From Your Bin to a New Can

The transformation of used aluminum cans into new products involves a sophisticated multi-step process that begins the moment you place a can in your recycling bin. Understanding this recycling made easy process reveals the impressive logistics and technology that make aluminum recycling one of the most efficient material recovery systems in the world, especially when recognizing common misconceptions addressed in common recycling myths busted.

1. Collection and Sorting

When aluminum cans enter the recycling stream through curbside collection or drop-off programs, they first arrive at a materials recovery facility where sophisticated sorting processes separate different types of recyclable materials. These facilities use magnetic separation technology to remove steel and iron materials, since magnets attract ferrous metals but have no effect on aluminum.

The key technology for isolating aluminum involves eddy current separators, which use rapidly rotating magnetic fields to create electrical currents in non-ferrous metals like aluminum. These currents generate magnetic fields that repel the aluminum pieces, literally throwing them off conveyor belts into separate collection areas. This process allows facilities to efficiently separate aluminum from plastic, glass, and other non-ferrous metals with remarkable precision.

2. Cleaning and Shredding

Once sorted, recycled cans undergo thorough cleaning to remove labels, ink, food residue, and other contaminants that could interfere with the melting and purification stages. Industrial washing systems use high-pressure water and specialized detergents to strip away surface materials while preserving the aluminum itself.

After cleaning, the cans are fed into powerful shredding machines that break them down into small aluminum flakes. This shredding process serves multiple purposes: it increases the surface area for more efficient melting, removes any remaining contaminants, and creates a uniform material that can be easily handled in subsequent processing steps. The resulting aluminum flakes are then screened and sorted by size to optimize furnace loading and ensure consistent melting characteristics.

3. Melting and Refining

The cleaned aluminum flakes are transported to specialized aluminum refining plants where they enter high-temperature furnaces designed specifically for secondary aluminum production. The machine heats the material to approximately 1,220°F (660°C), the melting point of aluminum, though industrial furnaces typically operate at higher temperatures to ensure complete melting and proper fluidity of the liquid metal.

During the melting process, any remaining organic materials like paint, lacquers, or adhesives vaporize and are captured by emission control systems. The molten aluminum is then subjected to purification treatments that remove impurities and adjust the chemical composition to meet specifications for new aluminum products. This refining process includes degassing to remove dissolved hydrogen, flux treatments to absorb non-metallic inclusions, and precise alloying to achieve desired material properties.

4. Recasting and Manufacturing

Once purified, the liquid metal is poured into large molds to form aluminum ingots, which are essentially blocks of solid aluminum that serve as the raw material for manufacturing new products. A single ingot created from recycled aluminum cans contains enough material to produce approximately 1.5 million new cans, demonstrating the remarkable efficiency of the aluminum recycling process.

These ingots are then transported to rolling mills, where they are reheated and processed through a series of rolling operations that gradually reduce thickness while increasing length. The resulting aluminum sheet is formed into coils that are shipped to manufacturers who transform them into new cans, automotive parts, window frames, and countless other aluminum products. The entire journey from recycling bin to store shelf can be completed in as little as 60 days, making aluminum one of the fastest-cycling recycled materials in commerce.

The Environmental Benefits of Aluminum Can Recycling

- Aluminum can recycling uses only 5% of the energy required to produce new aluminum from bauxite ore, significantly lowering greenhouse gas emissions and air pollution.

- The dramatic reduction in energy consumption also decreases demand on power plants, reducing climate impacts linked to fossil-fuel electricity generation.

- Recycling keeps millions of aluminum cans out of landfills, supporting zero-waste goals and preserving landfill space for non-recyclable materials, while also reinforcing the importance of responsible waste disposal.

- Each ton of recycled aluminum eliminates the need to mine approximately four tons of bauxite ore, protecting ecosystems and reducing habitat destruction.

- Recycling aluminum conserves additional natural resources, including water and chemicals, that would have been consumed during raw material extraction and processing.

- Transportation impacts are reduced, as recycled aluminum requires shorter shipping distances, decreasing fuel use, air pollution, and reliance on international supply chains.

The Future of Aluminum Recycling: Innovations and Trends

The future of aluminum recycling promises significant improvements in efficiency, quality, and environmental impact through the integration of cutting-edge technologies and innovative processing methods. Advanced sorting and separation technologies, including artificial intelligence and machine learning systems, are revolutionizing how recycling facilities identify and process aluminum materials.

Robotic systems equipped with sophisticated sensors and AI algorithms can now identify different types of aluminum alloys and contamination levels with unprecedented accuracy, improving sorting efficiency in ways similar to understanding how local trash pickup services work and their operational needs. These automated systems work continuously without fatigue and can adapt to variations in material composition that would challenge traditional sorting methods.

Investment in green technology and clean energy for recycling processes promises to further reduce the environmental impact of aluminum recycling while improving economic efficiency. Solar-powered facilities, waste heat recovery systems, and other sustainable technologies are being integrated into recycling operations to minimize energy consumption and greenhouse gas emissions.

The Ongoing Journey of Aluminum Recycling

Understanding what happens to recycled aluminum cans reveals just how powerful and sustainable the recycling process truly is. These cans transform into new products in as little as 60 days, conserving energy, reducing environmental impact, and supporting a circular economy that keeps valuable materials in use rather than in landfills.

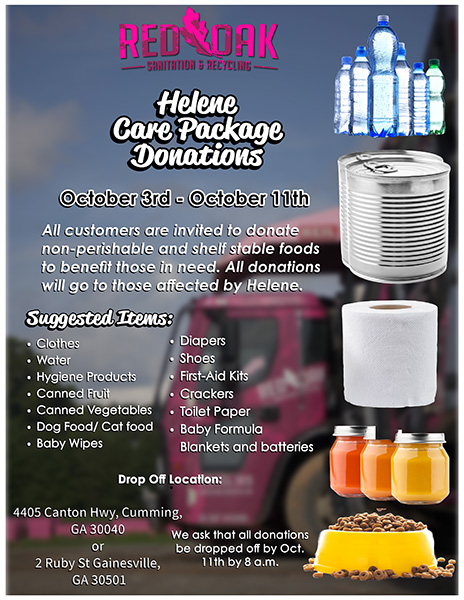

As you think about the role you play in this cycle, Red Oak Sanitation & Recycling remains committed to making responsible disposal and recycling more accessible. Whether you’re managing everyday recyclables or scheduling trash pickup in Atlanta, our services are designed to support cleaner communities and efficient waste solutions. Let us help you simplify your recycling habits with dependable yard waste, recycling made easy, and commercial services tailored to your needs. From curbside collection to full-service sanitation support, our team ensures your materials are processed responsibly, keeping resources in circulation and contributing to a more sustainable future for everyone.

Frequently Asked Questions

What happens to aluminum cans after they are collected for recycling?

After collection, aluminum cans are transported to a materials recovery facility where they’re sorted, cleaned, shredded, and melted. The purified molten aluminum is then cast into ingots, rolled into sheets, and manufactured into new cans or other aluminum products—often within just 60 days.

Why is aluminum considered one of the most valuable recyclable materials?

Aluminum retains its quality through infinite recycling cycles, meaning it never degrades. Recycling it saves up to 95% of the energy used in producing aluminum from raw materials, making it both economically valuable and environmentally essential.

How does aluminum recycling benefit the environment?

Recycling aluminum reduces greenhouse gas emissions, conserves natural resources like bauxite ore and water, minimizes landfill waste, and cuts transportation impacts. These combined benefits support sustainability goals and reduce the strain on waste management systems.

How long does it take for a recycled aluminum can to return to store shelves?

The aluminum recycling process is extremely fast. From curbside bin to new can, the entire cycle can take as little as 60 days, making aluminum one of the most efficiently recycled materials in the world.

What new technologies are improving aluminum recycling?

Innovations such as artificial intelligence, machine-learning sorting systems, robotic identification, and clean-energy-powered recycling facilities are transforming the industry. These technologies increase sorting accuracy, reduce contamination, and enhance the efficiency and sustainability of aluminum recycling.